In preservation of a liveable climate, Thailand stresses that greenhouse gas emissions must reach net-zero by 2065. The logistical supply chain run mostly on fossil fuels with its long haul transportation and large-scale warehousing being major culprits.

The logistics sector is looking to change this with sustainable solutions aimed at revolutionising the industry. Themed "Smart and Green Logistics for Sustainable Tomorrow", the annual TILOG-LOGISTIX logistics exhibition returns for its 6th edition with focus on sustainability and the latest green technological solutions in transportation, inventory management, material handling, packaging, as well as the most complete logistics-related management systems. Despite this, there still is demand for solutions that provide speedy order fulfilment for maximised efficiency.

With that, AutoStore, leaders in cube storage automation, announced its participation in TILOG-LOGISTIX to showcase their efficient eco-friendly logistics solutions at the Bangkok International Trade & Exhibition Centre (BITEC), Hall 98 Booth L10, from 17 to 19 August 2023.

Solutions on show

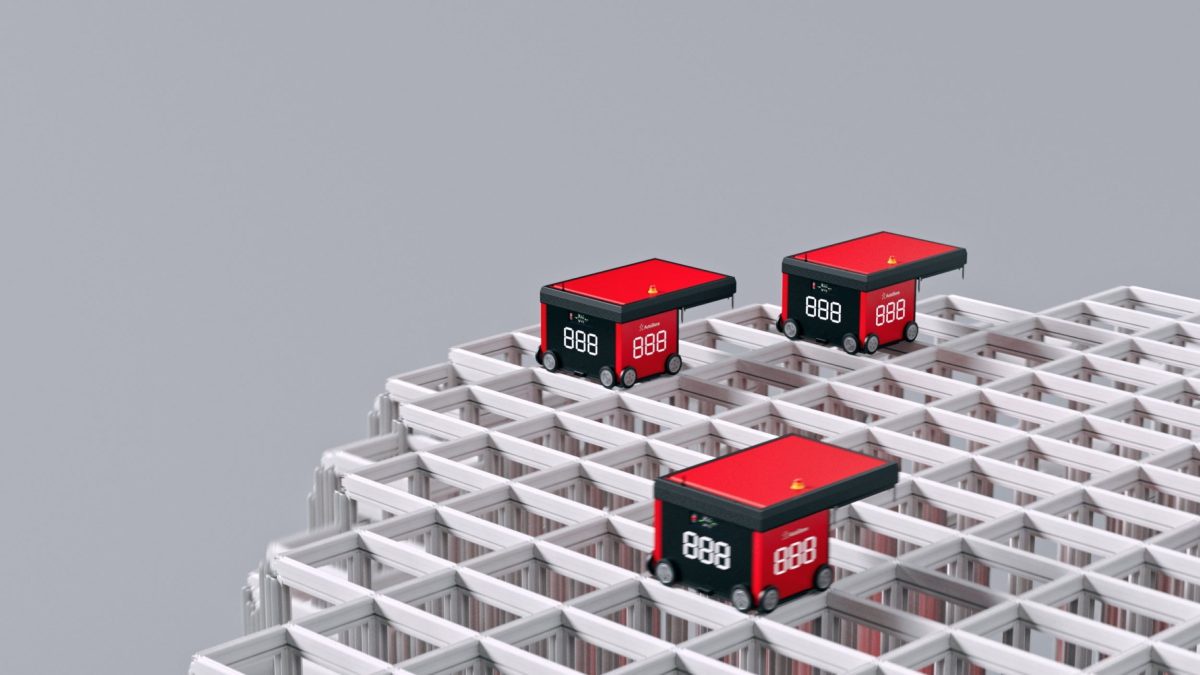

AutoStore will showcase the "Vending Machine", a medium-size grid with two signature workstations, also known as "ports" - the ConveyorPort on the grid with CarouselPort furniture at the side typically seen in warehouses of various industries including retail, grocery, 3PL, healthcare among others. The "Vending Machine" contains 2 R5 robots and their robot chargers, along with 60 storage bins of 330mm height for its storage and retrieval purposes.

Essentially, ConveyorPort is a workstation in its simplest form. Bins are dropped on a conveyor and transferred to an opening outside of the grid, where smart covering and sensors keep the operation safe for the operator. The CarouselPort is designed to work with operators in harmony with robots to ensure the next bin is always ready. The workstation operates with three rotating arms, each holding one bin tray. Two arms are positioned in the back of the port for robots to place or retrieve bins. The third arm is in the front position for picker access to the goods inside the bin.

The carousel movement ensures continuous operation at any warehouse. Its latest design, CarouselPort 4.0, has a redesigned safety cover that slides freely in all directions, and a new safety box with additional emergency stop options. These enhancements maximise CarouselPort's efficiency, usability, and safety while lowering operating costs.

An energy efficient yet speedy technological solution

In line with the exhibition's theme of sustainability, an AutoStore storage system with ten robots uses approximately the same amount of energy as a vacuum cleaner operating for the same amount of time.

These robots not only recharge themselves at the right time to avoid excessive charging, but also has regenerative energy functions to recharge their batteries whenever they lower a bin or reduce speed. All in all, they only consume 100 Watts of energy, potentially lowering warehouse operation expenses.

Despite being so energy efficient, choosing the AutoStore robotic warehouse solution gives businesses the fastest order fulfilment system per square foot on the market. The system fulfils orders at speeds up to 650 bins per hour for every port - all while significantly lowering energy consumption and warehouse operation cost.

Reducing warehouse footprint while increasing efficiency

With real estate becoming a premium in cities coupled with the increase in e-commerce demands, AutoStore showcases its unique cube storage system which is designed for easy system expansion without the need to take up more floor space and relocating the warehouse premises.

It optimises available space with a modular-based building block design that expands upwards to accommodate growing warehouse capacity needs. The system is highly scalable and space saving, allowing for four times the storage capacity within the same footprint, with its 99.7% uptime enabling 24/7 access to inventory and increased efficiency in order fulfilment. The system's 99.9% picking accuracy also increases productivity and minimises errors, leading to fewer returns and happier customers. Across the world, AutoStore has helped install over 1,150 systems globally, with more than 115 customers coming from the Asia-Pacific region.

"As the world continues to witness the urgent need for sustainable business practices, the logistics industry faces a pivotal challenge to reduce its environmental impact. We are thrilled to participate in this crucial event that highlights the importance of sustainability in the logistics industry," said Philipp Schitter, Vice President of Business Development Asia Pacific for AutoStore.

"By integrating greener warehousing solutions into the operations of businesses within Thailand, we believe that it not only drive positive change but help businesses cope with space and speed constraints the logistics landscape faces today."

Keen to learn more? Visit us at BITEC, Hall 98 Booth L10, from 17 to 19 August 2023 and catch our cube storage warehousing solution in action!

Source: Mind PR