Universal Robots, the Danish collaborative robot (cobot) company, has urged electric vehicle (EV) manufacturers in Thailand to adopt cobots to aid production amid accelerated growth within the market. Amid climate change, rising oil prices, government policies, and stricter emission standards, there has been a massive global shift to EVs over conventional internal combustion engine vehicles. Thailand has jumped on this bandwagon early, taking steps to become the region's EV production hub.

The Thai EV Market and Becoming the Region's Hub

Fresh off last year's production agreement with Chinese electric car giant BYD, the Thai EV market is projected to reach US$178.80m in 2023, and is expected to show an annual growth rate of 22.31% through to 2027. This agreement falls in line with the Thai government's plan to transform 30% of all its total auto production to EVs by 2030.

It aims to start producing 150,000 passenger cars per year from 2024, with a sales target of 10,000 units to be sold locally. The other units are planned to be exported to Southeast Asian and European countries, cementing Thailand's role as the EV production hub within the region. "Thailand has put herself at the forefront of the incoming EV wave in automation, and the policies along with agreements with electric car manufacturers show a major shift in focus," said Thanakrit Thaneerat, Universal Robots Country Manager, Thailand. "With ambitions in the manufacturing of EVs and making the country the region's EV hub, there will be issues arising within the manufacturing industry that cobots can aid with."

Cobots and Alleviating Manufacturing Issues

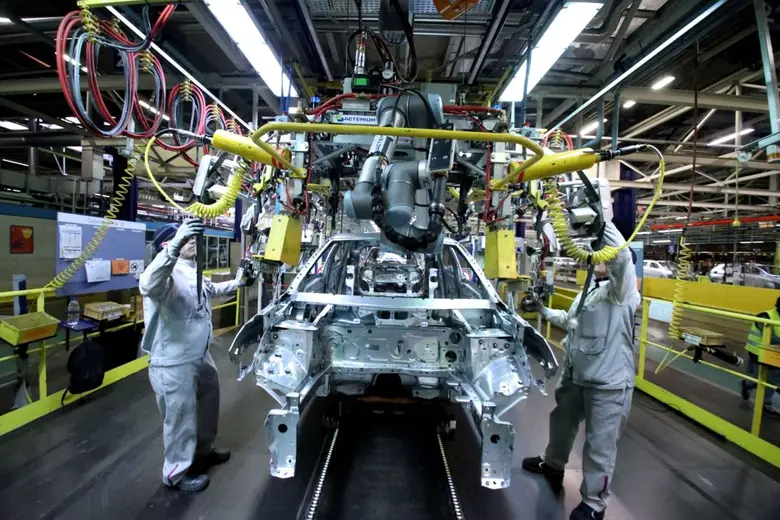

To aid the country's journey to becoming ASEAN's EV production hub, the implementation of cobots can solve various issues faced within the manufacturing industry. As some of the assembly process requires the introduction of specific automation technologies to ensure product standards, cobots offer the solution for manufacturers.

Production criteria includes quality and repeatability, ergonomics, operating precision, as well as quality. Collaborative applications help address these operational issues, improving the series of production tasks previously performed manually. "Cobots can help guarantee the quality requirements as well as free operators from repetitive and physically demanding manual tasks," said Thanakrit. "The marvel of man-machine collaboration is that it allows workers to be stationed at processes that are of greater value and require the human touch."

Elsewhere, the iconic Fiat 500 has also jumped onto the EV bandwagon, with the Italian brand now offering an electric variant of the car. This shift meant that the car's production line required the introduction of specific automation technologies to meet product standards. This, along with the staff's high average age, prompted them to adopt 11 UR cobots at the factory to aid with production. The cobots helped with tasks which include the application of waterproof liner to vehicle doors, checking on soft-top dimensions, hood mounting, and tightening of rear-side door hinges among others.

Keeping Up with Automation and Ensuring Growth

As Thailand grows into becoming the region's EV manufacturing hub, automation will be key to growth within the industry. "With the EV manufacturing industry being one of the country's strengths, it is important to strengthen the grip instead of being complacent and falling behind others," said Thanakrit.

Thailand's robot density in the manufacturing sector was behind the global average in 2019, and has been lagging behind regional counterparts such as Singapore. However, Thailand gained 36% in their population of robotics in 2021, and the continued upward trajectory will further improve multiple sectors, including the EV manufacturing one. "Overall, the adoption of automation will help with productiveness, and profitability due to its effectiveness and efficiency. It will further improve the industry and make it more appealing for investors, which in turn will ensure further growth for the sector."

About Universal Robots

Universal Robots aims to empower change in the way work is done using its leading-edge robotics platform. Since introducing the world's first commercially viable collaborative robot (cobot) in 2008, UR has developed a product portfolio including the UR3e, UR5e, UR10e, UR16e and UR20, reflecting a range of reaches and payloads. Each model is supported by a wide selection of end-effectors, software, accessories and application kits in the UR+ ecosystem. This allows the cobots to be used across a wide range of industries and means that they can be redeployed across diverse tasks. The company, which is part of Teradyne Inc., is headquartered in Odense, Denmark, and has offices in the USA, Germany, France, Spain, Italy, the Czech Republic, Romania, Turkey, China, India, Japan, South Korea, Singapore and Mexico.

Universal Robots has installed over 50,000 cobots worldwide. For more information, please visit www.universal-robots.com.