Ajinomoto (Thailand), a global leader in the food industry, is continuing with its commitment to creating sustainable well-being for Thai society. The "Eat Well, Live Well" approach encompasses all aspects, including social impacts and environmental responsibility. The company is updating its operational plans with a mission of extending healthy lifespans for people worldwide. This approach leverages "AminoScience" and aims to transform Ajinomoto into a low-carbon business. This ambitious goal is to successfully reduce their environmental impact by 50% by 2030. Ajinomoto's Kamphaeng Phet Factory serves as a model of an eco-friendly factory, reinforcing their commitment to achieving Net Zero emissions. Additionally, Ajinomoto has launched a new business, Ajinomoto FD Green, to develop and support sustainable agriculture. This initiative promotes well-being among Thais from upstream to downstream across the food production chain.

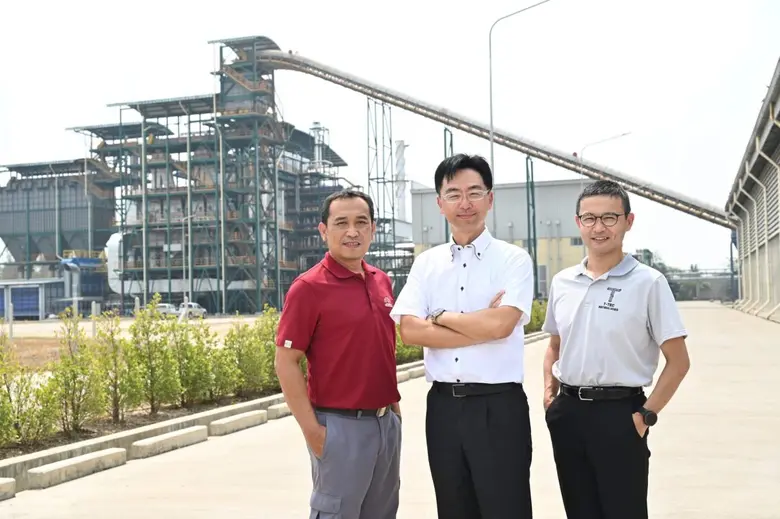

Mr. Kenji Harada, Vice President of Ajinomoto Co., (Thailand) Ltd., said, "Aligning with our global group's 2030 sustainability goals, Ajinomoto (Thailand) is leveraging 'the science of amino acids' (AminoScience) to create food and health innovations. We strive to achieve 'Eat Well, Live Well,' fulfilling our mission of extending the healthy life expectancy of one billion people worldwide by leveraging "AminoScience." This will be achieved by promoting the four key functions of amino acids: 1) flavoring food; 2) delivering nutrients to the body; 3) promoting good health; and 4) exploring new functional possibilities to create breakthrough health solutions.

Amino acids, considered the cornerstone of our core product, like AJI-NO-MOTO(R) MSG, are being further explored in dietary supplements, such as aminoVITAL(R) (BCAAs), which aid in muscle restoration and strengthening athletes and fitness enthusiasts, and AminoMOF (Leucine), which supports muscle and joint development, and is particularly beneficial for the elderly, helping them regain mobility and an active lifestyle. The company is continuously researching and developing products that will promote people's well-being around the world through our knowledge of AminoScience.

Additionally, our operational plan prioritizes minimizing environmental impacts from upstream to downstream, encompassing factory production, sustainable sourcing of raw materials, and household and agricultural sectors under the 'Ajinomoto Biocycle' concept, a comprehensive approach that aims to establish a low-carbon company, with a target of achieving a 50% reduction in environmental impact by 2030."

Action plan towards "Creating Global Sustainability" goals in 2030

Ajinomoto's action plan involves the following five operational guidelines to minimize environmental impacts resulting from business operations: 1) Reduce greenhouse gas emissions by 50%; 2) Preserve 80% of water resources; 3) Achieve zero plastic waste by using recyclable plastic;

4) Minimize food loss and waste throughout the company's operations; and 5) Procure 100% sustainable raw materials, which have been implemented towards concrete environmental sustainability as follows:

- The Factory Production Sector: By adopting alternative and renewable energy sources in the production process, the company has significantly reduced carbon dioxide emissions, saving over 380,000 tons annually. Modifications to utilize recyclable plastics and water-saving techniques per production unit. A reduction in food loss and waste by up to 70%, equivalent to approximately 1,300 tons. Additionally, Ajinomoto has introduced employee uniforms made from recycled PET plastic, further reducing the amount of plastic waste being generated. These combined efforts from our operations are contributing to Ajinomoto's goal of becoming a low-carbon company.

- The Sustainable Raw Material Sourcing Sector: Prioritizing responsible and sustainable sourcing practices, Ajinomoto mitigates environmental and social impacts throughout its procurement of raw materials and products across the supply chain. Initiatives over the past two years (2022-2023) include the adoption of 100% FSC certified paper, sourcing over 100% RSPO certified palm oil and palm products, and selecting pork from sources that focus on animal welfare.

- The Household Sector: Through the "Too Good To Waste" project, Ajinomoto is reducing food waste among consumers by promoting "Eco-friendly food recipes," improving awareness and encouraging sustainable consumption practices.

- The Agricultural Sector: Leveraging its expertise in amino acids through co-products obtained from the MSG production process, Ajinomoto supports farmers in sustainable product cultivation under the "Ajinomoto Biocycle" concept, which promotes a biological cycle in the production process.

Mr. Nuttapon Parnichdee, Kamphaeng Phet Factory Manager of Ajinomoto Co., (Thailand) Ltd., said, "Ajinomoto's Kamphaeng Phet Factory serves as a crucial production base, promoting well-being for Thais nationwide and in over 40 additional countries. It is an environmentally friendly factory that utilizes renewable energy sources to minimize carbon dioxide emissions. Examples include use of 'Biomass Energy Steam Boiler Technology' and developing a 'Biomass Cogeneration Power Plant' that uses leftover agricultural rice husks as fuel for production. Additionally, a solar roof system was installed for further renewable energy generation. An efficient water treatment system was implemented within the factory, applying the 3Rs (Reduce, Reuse, Recycle) principles, including reducing plastic use throughout production. These combined efforts contribute to a holistic approach to minimizing environmental impacts, ultimately promoting a sustainable positive cycle."

Dr. Kohei Ishikawa, President of Ajinomoto FD Green (Thailand) Co., Ltd., added, "As a global leader in the food industry, Ajinomoto prioritizes securing high-quality raw materials from upstream and takes care of every part of our value chain cycle. Regarding this commitment, Ajinomoto FD Green (Thailand) Co., Ltd.

was established as the group's 'business model company for the environment.' Ajinomoto FD Green aims to penetrate the agricultural sector to ensure the sustainable management of 'co-products' generated from MSG production, which are transformed into useful agricultural products. Currently, the company offers 11 products across two categories: 1) Agricultural products such as garlic, coffee beans 2) Agricultural products for plants and animal feed. Throughout this past period, we have continued to build on our knowledge to develop products that support improved crop performance for farmers. Recently, we introduced a new product called 'Amina Fertilizer,' which leverages Ajinomoto Company's expertise in fermentation technology. This biological fertilizer, rich in beneficial bacteria for plants, has been developed to promote root growth and increase soil nutrients. Consequently, the productivity of farmers has noticeably increased."

"We believe that strong relationships with thriving farmers are essential for our long-term success. Therefore, we actively promote sustainable agricultural practices, supporting more than 1,376 Thai farmer families in Kamphaeng Phet and Nakhon Sawan provinces, which are major cassava cultivation areas in Thailand. Our initiatives focus on two key projects:

- Thai Farmer Better Life Partner Project, which aims to elevate the well-being of farmers and create a positive, sustainable cycle. We focus on the entire cassava farm - a key raw material for Ajinomoto's MSG production, and have expanded this model to coffee farms that supply Birdy coffee. Through the Ajinomoto Bio-cycle concept, we create environmentally friendly organic fertilizer from fermented water that is left over from production. We collaborate with government and relevant agencies to provide knowledge, guidance, and ensure fair-priced purchases;

- Green Coffee Bean (GCB) Farmer Sustainability Project, which supports farmers in using organic chemical fertilizers developed through AminoScience technology, ultimately reducing reliance on chemical cultivation. We also provide knowledge on growing, maintaining, and harvesting coffee trees to ensure high-quality production. The aim is to grow Ajinomoto FD Green (Thailand) Co., Ltd.'s agricultural business by 2.5 times and develop a 100% traceability system for cassava sources in the Thai Farmer Better Life Partner project to achieve the goal of reducing other indirect greenhouse gas emissions by 2030.